Hydrocolloids and Cellulose for Technical Ceramics

Plant Based Leverage for Technical Ceramics

Among the materials suited for high perfomance applications, ceramics enjoy an exceptional reputation. Manufactured from carbides, nitrides or inorganic minerals, they offer phenomenal peculiarities such as extreme rigidity, impeccable temperature stability, and extraordinary wear and corrosion resistance at high temperature.

Driving markets for technical ceramics are electronics and electrics, automotive, energy and power as well as medical applications, just to name a few.

Cellulose as Pore Creator in Technical Ceramics

In technical ceramics, porosity is a defining parameter for the functionality of products. Desired properties like inner surface area, thermal and acoustic insulation and degree of permeability, capillary activity as well as density are directly related.

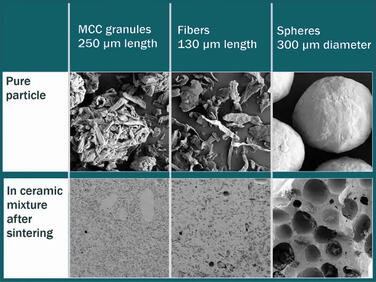

Together with the AdvancedCeramics group at the University of Bremen, we investigated the influence of fiber size, structure and quantity on the pore formation after burning.

Generally, it became clear, that the diameter in fibrous structures is the dominant dimension and accounts for a narrow pore size distribution. For more cubic and spherical forms, the contact areas between the particles results in wider pore size distributions after sintering.

In combination, structure and quantity of pore formers are suitable for controlling the final amount and shape of open pores.

Another positive effect of cellulose fibers is the even distribution of moisture in ceramic masses. This gives rise to shorter, more even drying which reduces cracks and fissures.

Hydrocolloids as Sustainable Binders

In extrusion of ceramic masses hydrocolloid binders are common. Within the industry, hydroxyethylcellulose (HEC or Tylose) is frequently used. The extrusion performance can be improved through substitution with HPMC. Another JRS specialty, microcrystalline cellulose gels, is supposed to make a positive impact in ceramics. More recent research goes into the direction of inotropic gelation with alginates and higher valent ions to create ceramic scaffolds of various shapes. Different gel or ceramic mass strengths can be achieved with alginates, as they can already form ultra-firm gels on their own.

Level Up Your Ceramics with Every Fiber.

Plants are our inspiration for innovations. They define our portfolio for enhancing your ceramics.