Natural Additives for Paper and Board

Wood Particles - The Efficient way of Paperboard Production

Who has not heard it? 'Reduce plastic consumption, develop paper solutions', summarized under this phrase is the trend for switching to regrowing materials in manifold applications. However, paper is not coming from nothing. Rather high investments in material, energy and workforce are necessary to craft paper from raw trees.

Therefore, the world has a huge need for improving the efficiency of paper production.

There are many different approaches to tackle this challenge, one is for sure to improve the recycling rate. Recycled paper has become a very valuable raw material for the production of various paper grades. It is also true, that the quality of the recycled paper decreases after several reuse cycles. The paper loses bulk as the fibers shorten with every round, mostly paper is not recycled more than 5-7 times.

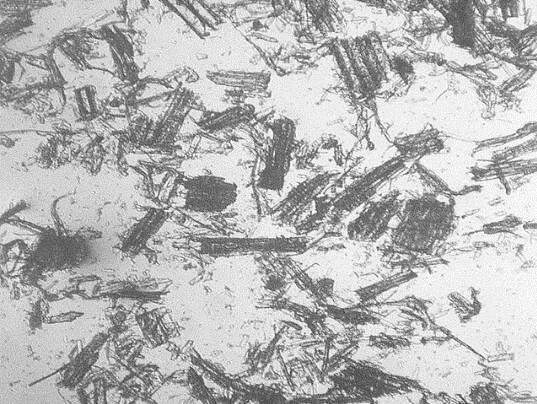

Now, to improve the paper quality again, it is possible to mix in more virgin fibers, or, which is the economic and ecologic solution, to add wood particles to increase the bulk again. Furthermore, wood additives improve drainage of water and result in an increased production speed. We already pointed this out in an earlier article. Since then, the energy prices went up and up and up, therefore it may now be the time to contact us.

Ultra Fine Cellulose Particles for Functional Paper Coatings

For paper finishing, a mixture of different binders like starch, latex and CMC as well as several additives like CaCO3 or Kaolin are used.

The idea is, to create an even surface with opacity and, depending on the application, barrier properties.

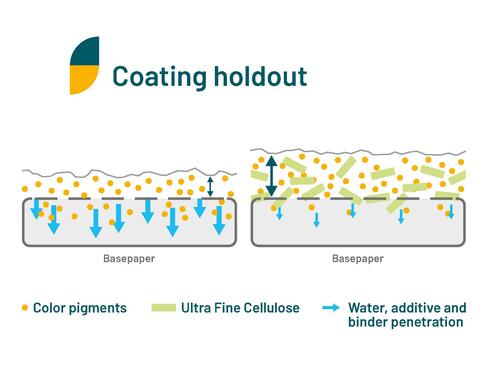

Here, very fine cellulose particles are an interesting tool to work with. In some of our case studies, an addition of only 0.6% (w/w) achieved significant improvements. The theory is, that the fine cellulose particles (d50 = ~10 µm) build up a barrier against other additives, water and binders, hindering them of penetrating too deep into the paper matrix.

This gives rise to manifold advantages in terms of coating quality, reduced material costs and energy savings.

In the end, it is an effective synergy of longer cellulose fibers in the basepaper and short ones on the surface.

Paper Coatings Coming from Fruit and Sea

You might have read a thing or two about our hydrocolloids in other blog articles. Prominent representatives are sodium alginates extracted from brown algae and pectin from citrus fruit peels, the remnants of juice production.

Dissolved in water and coated on a paper surface, these plant-based polymers exhibit excellent fat and oxygen barriers.

We have made some trials in order to optimize base formulations and are in contact with coaters and formulators who try them out in their systems.

We are keen to cooperate here, as this might open up a path to move away from synthetic additives who remain in the environment for ages. Hence, if you are active in this field, we are happy to answer your questions and dive into details.