Future Materials – Plastic Free

Collection & Processing

There are Algae and Citrus Fruits in the Headliner, is this a Food Blog now?

No not at all, we stay loyal to our chemical customers, but there are multiple materi-als used today in other industries such as food ingredients, which have tremendous potential in technical applications.

So why Alginate and Pectins what are they?

Sure, both are hydrocolloids and are natural polysaccharides, but furthermore they are excellent film formers and do react with multivalent cations, e.g. Calcium, in short: Highly promising and flexible future materials. However, they heavily differ in their feedstocks. JRS alginates are harvested at the Atlantic coast of France under strict regulatory supervisory, while our pectins are extracted from renewable side streams of the fruit juice and essential oils industry in Italy.

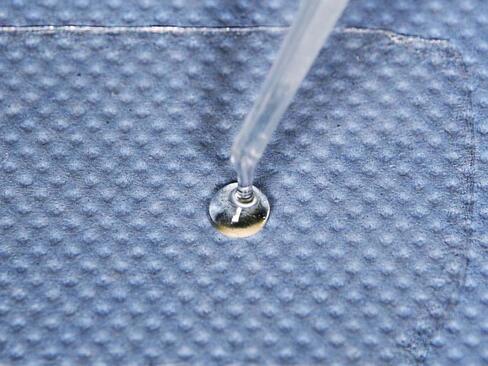

In most applications, the processing of alginate and pectin starts similar to most hy-drocolloids, they are dissolved in water, where they are often used as a rheology additive. But this is not always the final goal. As mentioned, both hydrocolloids can react with calcium. To do so, they form pockets around the cation and in the process form a water insoluble gel, coating or free standing film. In some cases even micro encapsulation.

Properties – Example Packaging Industry

Why Should I be Interested?

Beside the good properties perfect suitability as rheology agent and sheer thinning additive, an alginate film or coating has outstanding properties regarding oil and ox-ygen barrier.

With the right plasticizer and alginate grade, our R&D was able to generate a ~50 µm free alginate films with oxygen transmission rates (OTR) below 1.0 cm³ / (m² * d * 1.0 bar) @ 25°C and 50% relative humidity. Since this was possible in simple formula-tions without fine-tuning and basic equipment, a huge potential is expected in this field. Alginate containing films or coatings could therefore replace e.g. EVOH in packaging applications. In addition, these films are perfect oil barriers, passing the KIT 12 test easily.

While the films are hydrophilic by nature, they can be water insoluble or soluble de-pending on the content of Calcium. And best of all, they are completely bio-degradable! Nonetheless, we have to admit that some challenges remain, such as seal-ability of the films and the integration into water-proof multilayer systems. How-ever, we are convinced that these challenges will be solved by the industry.

So Alginates are Fascinating, but what About Pectins?

Pectins do add a completely new layer of complexity to hydrocolloids. There are three groups of commercially used pectins:

- High methoxyl pectin (HM) > 50% methoxy groups

- Low methoxyl pectin (LMC) < 50% methoxy groups

- Methoxyl amidated pectin (LMA)

These three groups all have distinct properties, but just to give you a short overview:

High methoxyl pectins (HM) can form thermostable gels under acidic conditions or in the presence of sugars. In addition, they have a positive synergy with alginate both in solutions, gels and in dried films.

Low methoxyl pectins (LMC) can form thermostable gels, too, but similar to alginate, they do so in the presence of Calcium. Like all of these three groups, they are film formers.

Methoxyl amidated pectins (LMA) can also form gels with multivalent cations (e.g. Calcium). However, in this system, the gels are thermo-reversible, Therefore they lose the gel characteristics under temperature and behave like a liquid again.

Interesting Indeed.. but how can I use it in my Applications?

Since these systems are new to various industries, we cannot possibly answer you this question on the spot, but we see many customers achieving pleasant results in packaging, adhesive, coating, micro-capsulation and other applications. This lists extends from month to month, so if you are now convinced to look into it, get into contact with our experts and we will support you to develop your system, where we can!

There is much more to the topic: For example, did we mention you can use different calcium salts and systems to incorporate a gelation delay of the system?

PS: While the usage of alginate and pectin in most technical applications is just starting, you may have already eaten alginate films as alternative casing for your (vegan) sausage!

Level Up Your Coatings with Every Fiber.

Bio-based binder, rheology additives and fillers for coatings.