Agents for Tableting, Mold Release and Disintegrants

Natural and Functional Fiber Agents for the Production of Fertilizer Tabs

Choose the most modern and sustainable way to optimize your production of fertilizer tabs:

Building on experience in virtually every industry sectors, JRS Plant Fiber Agents have proven to be true solution providers in tableting and disintegration, as well as problem solving like mold release!

Perfect Fusion! Our Technology, Your Experience.

We utilize all the possibilities of JRS Plant Fiber Technology to work together and create the optimal solutions for your needs. Your challenges are our passion!

What does value-added cooperation with JRS look like?

YOUR CHALLENGE:

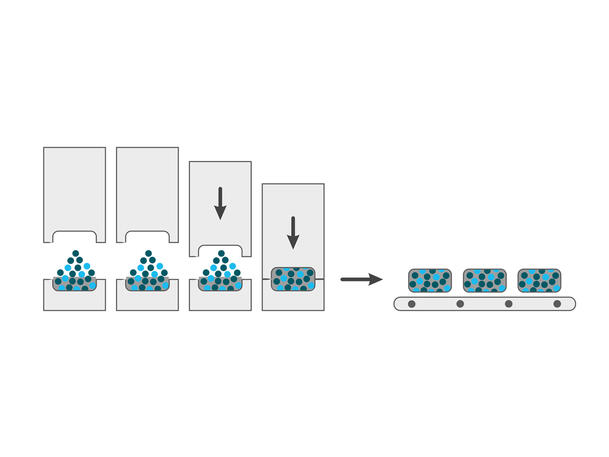

How to Improve Direct Tableting

Problem description:

Fertilizer and micronutrients are often cubic and hard to compact to stable tablets. Much force input is required. Nevertheless, tablets can be weak and breakable.

How to Solve It

Control tablet properties such as density, elasticity and deformability to enable direct tableting in a low-pressure, gentle, single-stage process.

Which Fiber Works

Functional agents of the ARBOCEL® Fiber Group and VIVAPUR® MCC (microcrystalline cellulose).

How It Works

Due to the crystallines uniform arrangement in a geometry, no large pressure input is required to form stable tablets.

How to Use It

Application amount depending on formulation, individual consulting by the JRS Technical Application Center.

Improve Your Tableting Processes

- Gentle tableting (without noticeable temperature rise)

- Low pressure tableting

- Suitable also for temperature and pressure-sensitive agents, such as microbes

- Fast, single-stage tableting

- No need for pre-compaction, no premixes with granulation necessary: many differently structured raw materials can be tableted in a single formulation

- JRS substances are free-flowing for dosing via hopper for tableting

- Compatible with all common tablet lubricants

- Enables the mixing of liquids on ARBOCEL® Carriers

… and the Product Properties of Your Fertilizer Tabs!

- Enables precise shapes of tabs and small tablets

- High compressive strength

- Homogeneous distribution of the ingredients

- Distribution (mixing) of the ingredients within the total volume

- Constant tablet weight

- Abrasion resistant for dust-free handling

- The dissolving behaviour of the tab can be controlled by individual pressure entry

YOUR CHALLENGE:

How to Avoid Adhesion to the Tableting Mold

Problem description:

Premix may stick to the mold during compression. Tabs become irregular in shape. This leads to many rejected tabs during production.

How to Solve It

Mold release agents prevent the tabs from sticking to the mold. Thus tabs go out of the molds faster and easier.

Which Fiber Works

JRS LUBRITAB® Hydrogenated Vegetable Oil

How It Works

By the connection of individual particles in the tab through the waxy structure, higher density is enabled. Thus, a sealed surface prevents sticking to the mold.

How to Use It

Addition of 0.3-0.5% to the total mix.

Improve Demolding

- Faster production with noticeably increased throughput, as tabs fall out of the mold faster

- Less fines in production: components fully adhere to the tablets

… and Achieve Perfectly Shaped Tabs!

- Exact shape

- Smooth surface

- Less abrassive

- Less breakable

How LUBRITAB® Makes Your Tabs More Stable!

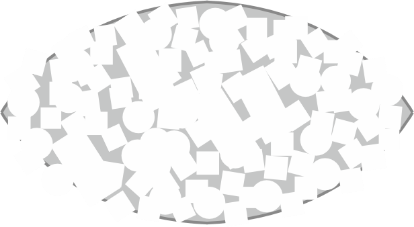

Without LUBRITAB®

Open, porous surface

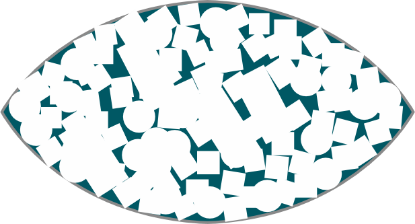

With LUBRITAB®

Perfect compression and closed surface

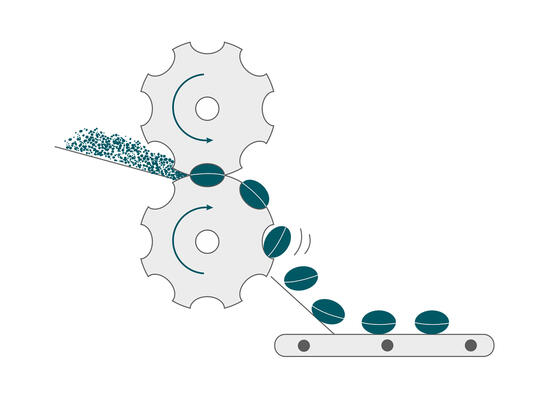

YOUR CHALLENGE:

How to Improve Fast Release in Soil or Watering Can

Problem description:

Many fertilizer actives in tabs or tablets require a strong compression to remain stable during transportation and storage. During application the high density prevents fast disintegration. Ingredients disperse slowly and don't become plant-available in short-term.

How to Solve It

Control the decay rate and enable an immediate release of all ingredients.

Which Fiber Works

ARBOCEL® celluloses and VIVASOL® croscarmellose.

How It Works

Cellulose fibers compressed to little granules give an "explosive effect" in tabs in the presence of water: The fibers allow a faster capillary transport of moisture into the tab matrix. As special swellable celluloses are used, there is a rapid, abrupt increase in the volume of the fine fiber granules. This leads to an immediate disintegration.

How to Use It

Dosage is dependent on density of the tabs and targeted decay rate. Individual consulting by JRS Technical Application Center.

In dry manufacturing processes ARBOCEL® is used. In wet manufacturing processes the same effect can be achieved with VIVASOL® croscarmellose.

Improve Disintegration Properties of Your Tabs!

- Fast, complete dissolution upon contact with irrigation water or use in a watering can

- Rapid availability of ingredients even when applied directly to moist soil and substrate

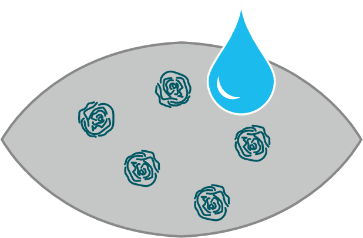

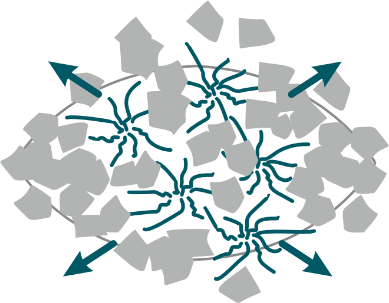

How Disintegration With ARBOCEL® Works:

ARBOCEL® fiber granules in dry tab

Disintegration Process

ARBOCEL® fiber expand after contact with water

Liquid to Solid Carrier

Conversion of various liquids (e.g. oils) into processable powders and granules: The application of liquids on inert JRS Fiber Carriers offers a smart way of integration in dry formulations. This opens up new possibilities in your recipes, even in very low concentrations.

Further Challenges and Solutions in Fertilizer

JRS Plant Fiber Technology has built a total-care system that focuses on all kinds of fertilizers. Using our functional plant fibers you can improve your production processes and optimize fertilizer properties in many ways.

Fertilizer Granules, Prills, Mini Prills

Liquid Fertilizers

Our Team is Happy to Support You

with any requests you have.

Please use the contact form below.

Phone consultation: +49 7967 152-424